Properties of Concrete in Hardening Stage

Concrete states:

Concrete has three different states:

- Plastic

- Setting

- Hardening

In each state it has different properties.

1) Plastic State:

When the concrete is first mixed it is like 'bread dough'. It is soft and can be worked or moulded into different shapes. In this state concrete is called PLASTIC. Concrete is plastic during placing and compaction. The most important properties of plastic concrete are workability and cohesiveness. A worker will sink into plastic concrete.

2) Setting State:

Concrete then begins to stiffen. The stiffening of concrete, when it is no longer soft, is called SETTING. Setting takes place after compaction and during finishing. Concrete that is sloppy or wet may be easy to place but will be more difficult to finish. A worker leaves footprints in setting concrete.

3) Hardening State:

After concrete has set it begins to gain strength and harden. The properties of hardened concrete are strength and durability. Hardened concrete will have no footprints on it if walked on.

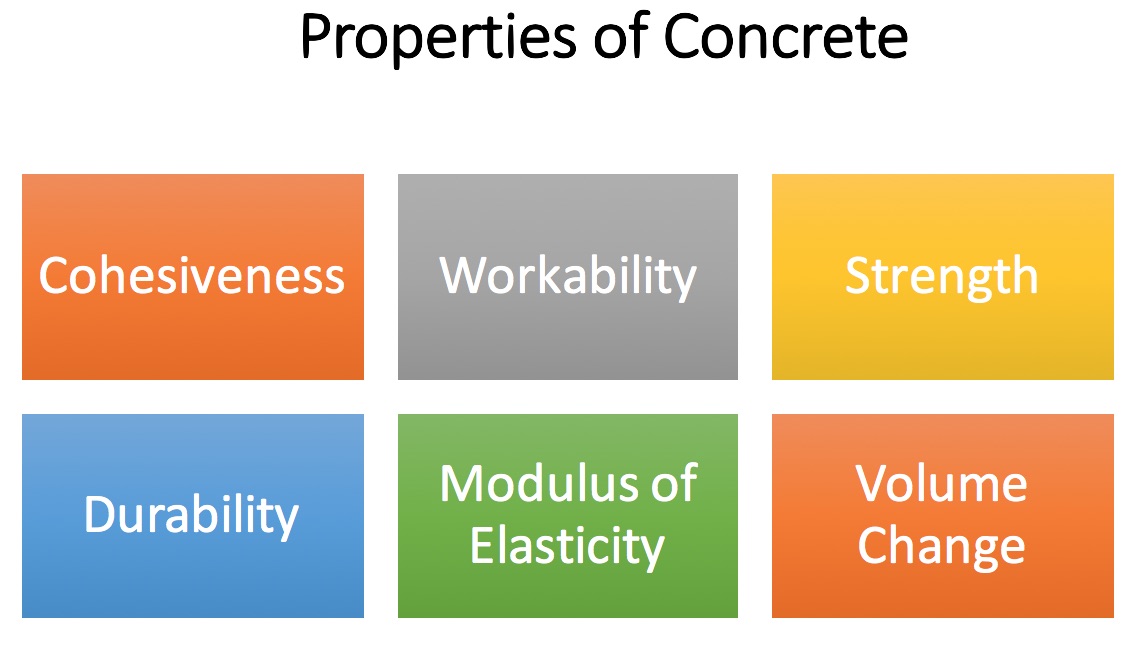

The Properties of Concrete are its characteristics or basic qualities. The main properties of concrete are:

- Cohesiveness and Hardness

- Workability

- Strength

- Durability

- Modulus of elasticity

- Volume change

i) Cohesiveness

Cohesiveness is how well concrete HOLDS TOGETHER when plastic. Cohesiveness is affected by:

THE AGGREGATE GRADING

Graded Aggregate means that there is a range of size of Aggregates, from large rocks to small sands.Well-graded Aggregates give a more cohesive mix, too much coarse Aggregate gives a boney mix.

WATER CONTENT

A mix that has too much water will not be cohesive and may separate and bleed. CURING Curing is keeping concrete damp for a period, to allow it to reach maximum strength. Longer curing will give more durable concrete.

WEATHER

Warmer weather will cause concrete to have a higher early strength.

TYPE OF CEMENT

Different types of cement will affect concrete properties: ie how quickly or slowly concrete gains strength.

THE WATER TO CEMENT RATIO

Too much water and not enough cement means concrete will be weaker and less durable. The water to cement ratio (W/C) is the weight of the water divided by the weight of cement.

ii) Workability:

Workability means how easy it is to:

- Place

- Handle

- Compact and

- Finish a concrete mix.

Concrete that is stiff or dry may be difficult to Handle and, if not constructed properly, will not be as strong or durable when finally hardened. A slump test can be used to measure the workability of concrete. In design mix the worker should keep the following points in mind to achieve the desired degree of workability.

- The amount of cement paste

- Distance of transport

- Strength and Durability

- Method of placing

- Loss of slump

The amount of cement paste:

The cement paste is the soft or liquid part of the concrete mix. The more paste mixed with the coarse and fine Aggregates, the more workable a mix. The aggregate grading: Well-graded, smooth, rounded aggregates improve the workability of a mix. To make a more workable mix: Add more CEMENT PASTE. Use WELL GRADED aggregates.

Admixtures:

Use an ADMIXTURE. Never try to make a mixture more workable by just adding more water because this lowers the strength and durability of concrete.

Strength and Durability:

Well made concrete is a naturally strong and durable material. It is DENSE, reasonably WATERTIGHT, able to resist changes in TEMPERATURE, as well as wear and tear from WEATHERING. Strength and Durability are affected by the density of the concrete. Denser concrete is more watertight (or less permeable). Concrete durability INCREASES with strength. Well made concrete is very important to protect the steel in reinforced concrete.

Use of admixtures:

Use of air entraining agent produces air bubbles which acts as a sort of ball bearing between particles and increases mobility, workability and decreases bleeding, segregation. The use of fine pozzolanic materials also have better lubricating effect and more work-ability.

iii) Strength:

iv) Durability:

v) Modulus of Elasticity:

This property is used in all design, but it is seldom determined by test, and almost never as a regular routine test. For important projects, it is best to secure this information at least once, during the tests on the trial batches at the various curing ages. An accurate value will be useful in prescribing camber or avoiding unusual deflections. An exact value of Ec is invaluable for long- span, thin-shell construction, where deflections can be large and must be predicted accurately for proper construction and timing removal of forms.

vi) Volume change:

Expansion and shrinkage

Concrete has a very low coefficient of thermal expansion. However if no provision is made for expansion very large forces can be created, causing cracks in parts of the structure not capable of withstanding the force or the repeated cycles of expansion and contraction.

As concrete matures it continues to shrink, due to the ongoing reaction taking place in the material, although the rate of shrinkage falls relatively quickly and keeps reducing over time (for all practical purposes concrete is usually considered to not shrink any further after 30 years). The relative shrinkage and expansion of concrete and brickwork require careful accommodation when the two forms of construction interface.

Because concrete is continuously shrinking for years after it is initially placed, it is generally accepted that under thermal loading it will never expand to it's originally-placed volume.