Quasi Static Test - How and Why the Test is Conducted?

Quasi static testing is a valuable experimental technique used in structural engineering to evaluate the behavior and performance of structures under controlled loading conditions. This article aims to provide an overview of what quasi-static testing entails, why it is conducted, and how the testing is performed.

What is Quasi Static Testing?

Quasi-static testing involves subjecting a structure or a component to slow and controlled loading, simulating static or near-static conditions. Unlike dynamic testing that mimics rapid loading rates, quasi-static tests apply loads at a slower rate to allow for accurate measurements and observations of structural response. The loading rate is adjusted to represent real-world conditions and assess the structural behavior under different loading scenarios.

Why is Quasi-Static Testing Conducted?

Quasi-static testing serves several purposes in structural engineering:

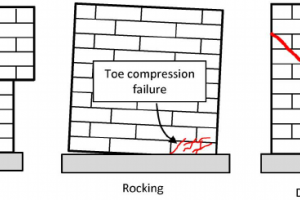

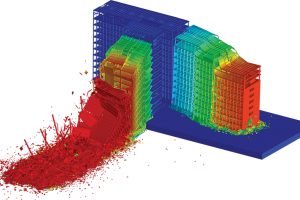

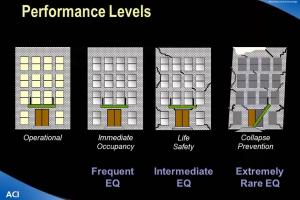

a. Structural Performance Evaluation: Quasi-static tests help engineers understand how structures and components behave under various loading conditions, providing valuable insights into their performance, strengths, weaknesses, and failure mechanisms.

b. Validation of Analytical Models: Quasi-static tests serve as a means to validate analytical models and computational simulations by comparing the predicted behavior with the actual experimental results. This helps improve the accuracy and reliability of analytical methods.

c. Development of Design Guidelines: Quasi-static testing generates data that contributes to the development of design guidelines and standards for structural systems. The insights gained from testing help refine design methodologies and enhance the safety and reliability of structures.

How is Quasi Static Testing Performed?

The process of quasi-static testing involves the following steps:

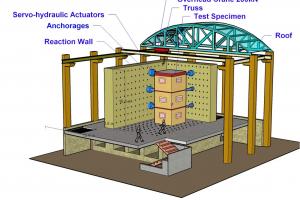

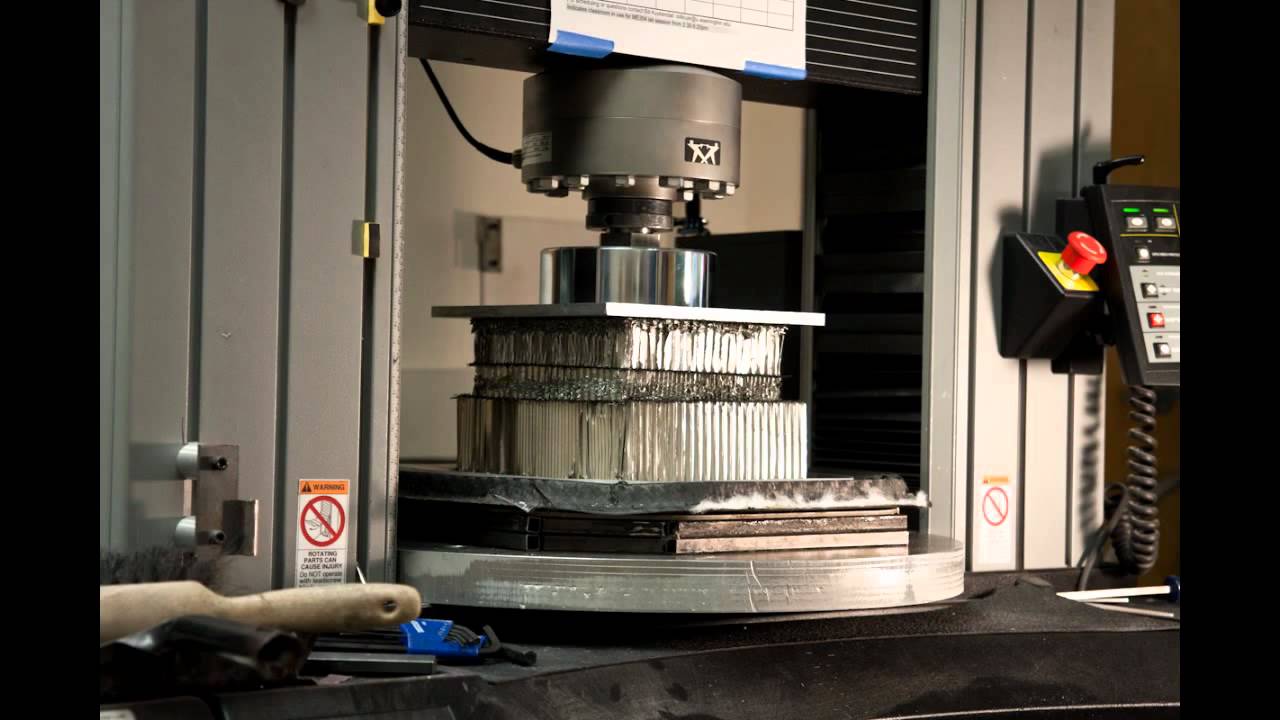

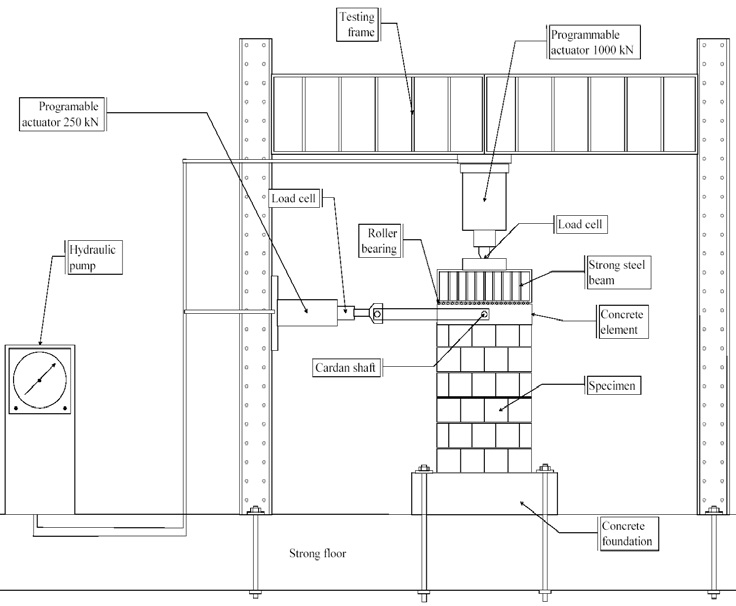

a. Test Setup: A representative specimen or structural component is selected for testing. The specimen is prepared and instrumented with sensors to measure various parameters such as displacements, strains, and forces. The specimen is securely mounted in a test setup, often using strong hydraulic actuators or load frames.

b. Load Application: The load is applied incrementally or continuously to the specimen, following a predetermined loading protocol. The loading may be uniaxial, biaxial, or multiaxial, depending on the testing objectives. The loading rate is adjusted to simulate realistic conditions, allowing sufficient time for data collection and observations.

c. Data Collection and Analysis: Throughout the test, data from the instrumentation sensors is collected and recorded. This includes measurements of displacements, strains, and forces. The collected data is analyzed to assess the structural behavior, including stiffness, strength, deformation patterns, and failure modes.

d. Test Completion and Evaluation: Once the desired load levels or failure criteria are reached, the test is concluded. The test results are evaluated, and the structural response is compared with the expected or predicted behavior. These findings inform subsequent design considerations, retrofitting strategies, or further research efforts.

Quasi Static Testing

Quasi-static testing provides valuable insights into the behavior and performance of structures under controlled loading conditions. By conducting quasi-static tests, engineers can enhance their understanding of structural systems, validate analytical models, and improve design methodologies. This experimental technique plays a crucial role in advancing the field of structural engineering and ensuring the safety and reliability of constructed environments.

The quasi static cyclic tests can be used to conduct both basic and proof tests. In quasi-static tests, loads and/ or displacements are applied at slow rates.

Normally, such types of tests are carried out to study the structural performance of structures and structural members such as the rate of propagation of cracks, the hierarchy of collapse and associated levels of damage, etc. A typical setup for quasi-static testing installed at the National Building Institute in Ljubljana, Slovenia is shown in Figure 1.

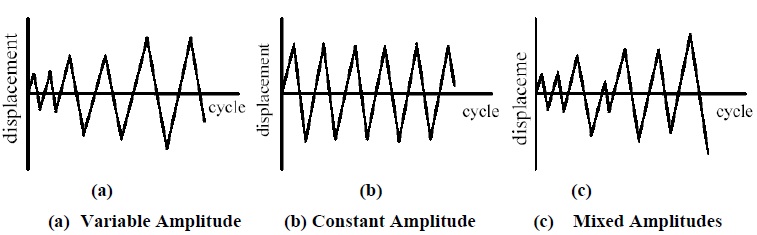

Quasi-static tests are performed by imposing predefined displacement or force histories on the testing specimen. Different types of displacement histories employed for conducted quasi-static tests are shown in Figure 2.

The slow loading rate during the test has the advantage of providing insight into the behavior of a structure/structural member in the post-yielding regime. However, the associated disadvantage is that the effects of acceleration-dependent inertial forces and velocity-dependent damping forces are eliminated, which can be significant for some structural types.

Similarly, by using the jacks and actuators the external actions are 'lumped' into the structure. These actions try to simulate the inertial forces that are developed due to mass on the structure. Consequently, the technique is not useful for structures possessing distributed mass such as hydraulic structures. However, many structures can be adequately modeled with lumped masses in a discretized manner and therefore are not affected by this restriction.