Disadvantages of Concrete in Construction

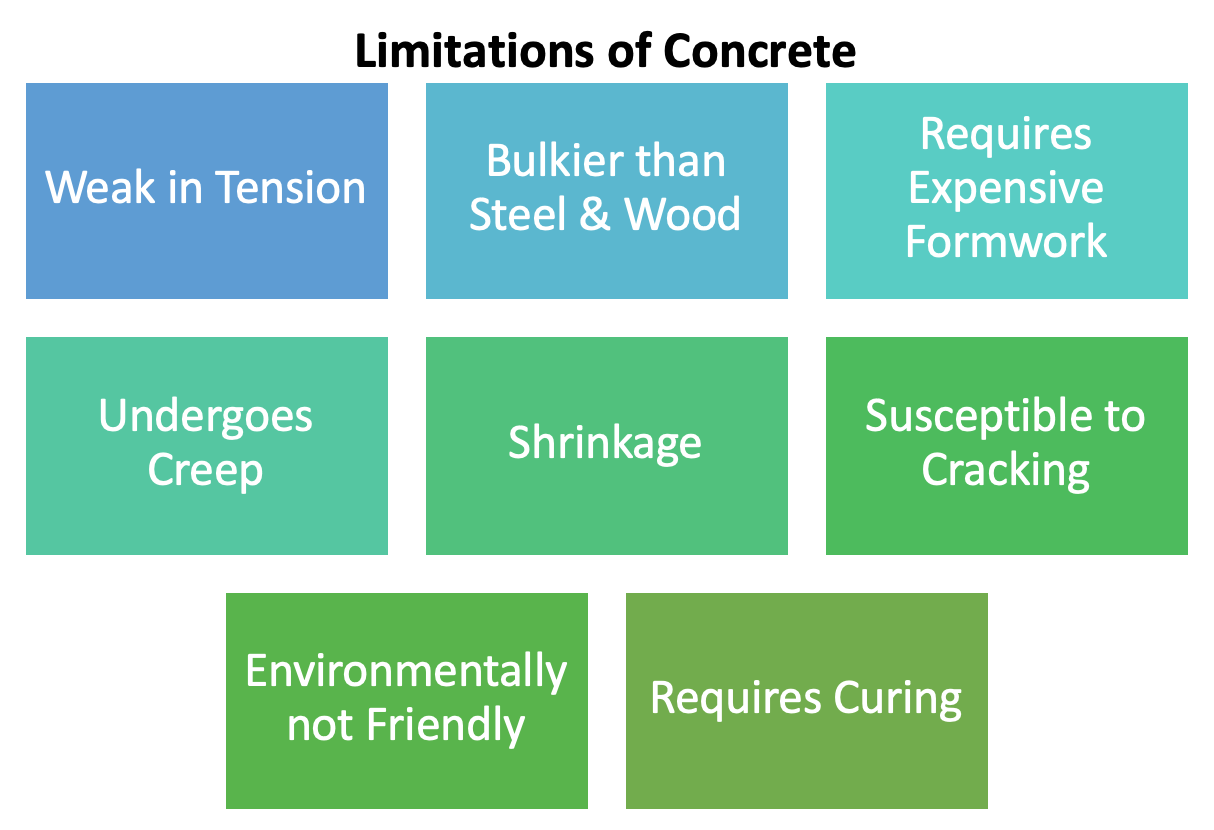

Limitations of Concrete

The disadvantages of Concrete are as follows:

- Concrete has a very low tensile strength and requires the use of reinforcing bars in the concrete tensile zone.

- Expensive formwork is required for casting and molding and to hold the concrete in place until it hardens sufficiently.

- The low strength per unit of weight of concrete leads to heavy members and is an important consideration for tall buildings and long-span structures resulting in disadvantages of Concrete

- The properties of concrete vary widely due to variations in its proportioning and mixing.

- The placing and curing of concrete are not as carefully controlled as the production of other materials such as structural steel and laminated wood.

- Another Disadvantage of Concrete is that Concrete is not ductile.

- Concrete is quasi-brittle and exhibits a strain-softening behavior

- Compared to steel, concrete has significantly low toughness. The toughness of concrete is only 1-2% of steel.

- Shrinkage in concrete causes cracks are developed and strength loss.

- Concrete requires the installation of formwork to mold it into a shape and to support its self-weight.

- Full-strength development in concrete requires proper curing for up to 28 days which means that concrete requires extra care and a good amount of water which makes it a disadvantage.

- The process of manufacturing concrete is not environment-friendly as it uses a lot more energy and emits greater volumes of carbon dioxide than other construction materials such as steel and glass.

- Concrete is susceptible to cracking. There are different types and causes of cracking

- Concrete is bulkier than steel or wood, increasing the dead load of the structure.

- Can experience concrete creep – increase in deformation over time with sustained loading.

- Can experience shrinkage – decrease in volume due to loss of absorbed water.

Properties of Fresh Concrete | Properties of Hard Concrete | Types of Concrete