Headrace Tunnels - Definition, Uses and Types of Headrace Tunnels

Definition

There are different definitions for headrace tunnels (HRT) used in different scenarios. “Headrace tunnel takes water from connecting channels and conveys it to the forebay or directly to the penstock provided with surge shaft” depending upon the project and site requirements times also known as power tunnels. Or

“A tunnel provided between the De-silting chamber or Fore-bay to the Surge Shaft” or “A structure that carries water from intake to the powerhouse for power generation”

Tunnels are very important components of any type of hydropower project and can be very useful in the long run. Now day’s highly sophisticated machines are used for tunneling such as TBM (Tunnel Boring Machine) which can accomplish the work in months and may take even years to be completed using manual procedures.

Headrace tunnels are very useful if the topography is not favorable for gravity channels such as irregular terrain, heavy vegetation, long route, social issues, etc.

Uses of Headrace Tunnels

Headrace tunnels are an essential component of hydropower systems, specifically those that use dams and reservoirs to generate electricity. The primary purpose of a headrace tunnel is to convey water from the reservoir or intake structure to the powerhouse, where it drives turbines to produce electricity. Here are some of the main uses of headrace tunnels:

1. Water Conveyance:

Headrace tunnels provide a conduit for the controlled flow of water from the reservoir or intake to the powerhouse. They ensure a steady and reliable water supply to the turbines, optimizing power generation.

2. Pressure Control:

The length and gradient of headrace tunnels can be designed to control the pressure of water as it moves toward the powerhouse. By managing the pressure, the speed and force of the water can be regulated to maximize turbine efficiency.

3. Energy Transfer:

As water flows through the headrace tunnel, it possesses potential energy due to its elevation above the turbines. This potential energy is converted into kinetic energy as the water descends toward the powerhouse, driving the turbines and generating electricity.

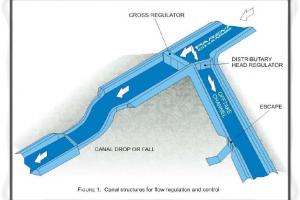

4. Flow Regulation:

Headrace tunnels can include control gates, valves, and other mechanisms to regulate the flow of water. These features allow operators to manage water flow based on electricity demand, seasonal variations, and other factors.

5. Protection from Natural Hazards:

Headrace tunnels are often constructed underground or within mountains to protect them from natural hazards like landslides, earthquakes, and extreme weather events. This underground placement ensures the reliability and safety of the water conveyance system.

6. Minimization of Environmental Impact:

By utilizing headrace tunnels, hydropower projects can minimize their environmental impact. Tunneling can help avoid excessive water drawdowns, reduce the extent of land submergence, and maintain natural river flows.

7. Cost Efficiency:

Headrace tunnels can optimize the efficiency of power generation by allowing for longer flow paths, which results in higher hydraulic heads and increased power output. This efficiency contributes to cost-effective electricity production.

Overall, headrace tunnels play a crucial role in the operation of hydropower plants by efficiently conveying water from the reservoir to the turbines while providing control, protection, and optimizing power generation.

Types of Headrace Tunnels

Types on the basis of flow

1. Pressure Flow Tunnels:

Pressure flow tunnels are designed to maintain a constant pressure within the tunnel, ensuring an efficient flow of water. They are typically used in situations where the water level in the reservoir is higher than the powerhouse. The pressure in these tunnels is usually high enough to keep the water flowing continuously without the need for additional pumping. Pressure flow tunnels are commonly used in high-head hydropower projects.

Example: The headrace tunnel of the Itaipu Dam in Brazil and Paraguay is a notable example of a pressure flow tunnel. It carries water from the reservoir to the powerhouse, generating a significant amount of electricity.

2. Gravity Flow Tunnels:

Gravity flow tunnels rely on the natural slope of the terrain to facilitate the flow of water. They are typically used when the water source is located at a higher elevation than the powerhouse. Gravity flow tunnels do not require additional energy for water conveyance since the water naturally flows downhill due to gravity. These tunnels are commonly used in low-head hydropower projects.

Example: The headrace tunnel of the Three Gorges Dam in China is a prominent example of a gravity flow tunnel. It utilizes the natural gradient of the terrain to transport water from the reservoir to the turbines.

Types of Headrace Tunnels based on Shape:

1. Semicircular Tunnels:

Semicircular tunnels have a cross-section resembling half of a circle. This shape provides good structural strength, making them suitable for a wide range of geological conditions. Semicircular tunnels are often preferred when the surrounding rock or soil is stable and can support the tunnel structure.

2. Circular Tunnels:

Circular tunnels have a cross-section in the shape of a complete circle. This shape offers excellent structural integrity and is commonly used when stability and strength are crucial considerations. Circular tunnels can efficiently withstand external pressure and are suitable for various ground conditions.

3. Elliptical Tunnels:

Elliptical tunnels have a cross-section in the shape of an ellipse. The elliptical shape provides an efficient balance between structural strength and space utilization. These tunnels are often used when there are constraints on the available space or when stability requirements necessitate a non-circular shape.

4. Horseshoe Tunnels:

Horseshoe tunnels have a cross-section resembling the shape of a horseshoe or the letter "U." This shape offers good structural stability and is commonly used in areas with weak or unstable rock formations. The horseshoe shape provides enhanced support against ground pressures.

5. Square with Arched Ceiling Tunnels:

These tunnels have a square cross-section with an arched ceiling. The square shape allows for efficient use of space, while the arched ceiling enhances structural strength. This type of tunnel is often employed when there is a need for increased clearance height or when the surrounding terrain requires a square shape for better stability.

The selection of the tunnel type and shape depends on various factors such as topography, geology, available space, water flow conditions, and structural considerations. Each type and shape of headrace tunnel has its advantages and is chosen based on the specific requirements of the hydropower project.