Material Composition of a Brick

Composition of a Brick

Bricks have been an integral part of construction for centuries, serving as the building blocks of countless structures. The composition of bricks plays a crucial role in determining their properties, strength, durability, and suitability for different applications. Understanding the composition of bricks is essential for architects, engineers, and builders to make informed decisions about their usage in construction projects. In this article, we will delve into the composition of bricks and explore the materials that contribute to their construction.

Normally, a brick contains the following ingredients by weight:

|

Ingredient |

% age by Weight |

|

Silica (Sand) |

50% to 60% |

|

Alumina (Clay) |

20% to 30% |

|

Lime |

2% to 5% |

|

Iron oxide |

Less than 7% |

|

Magnesia |

Less than 1% |

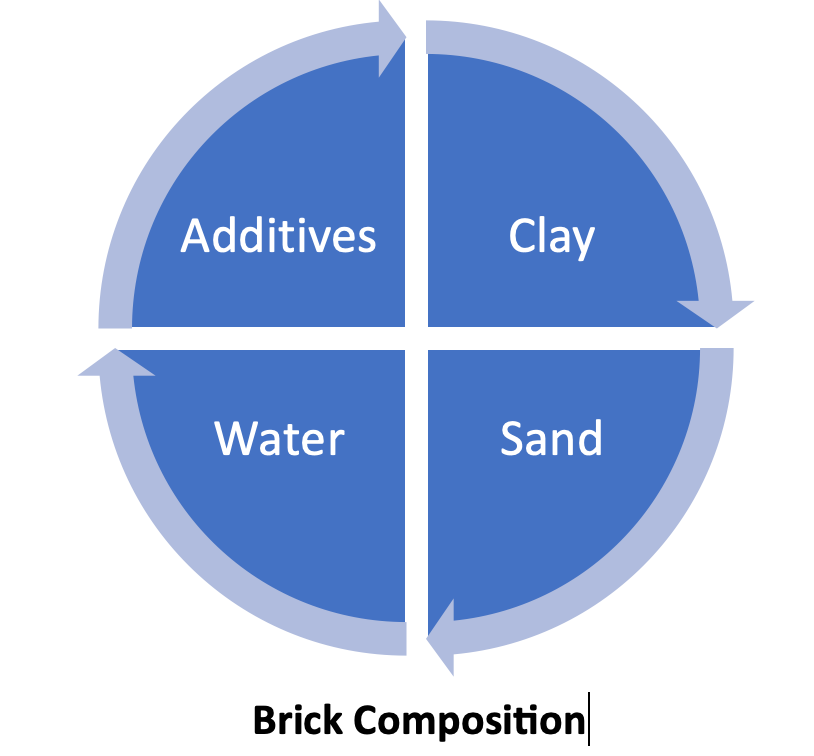

Clay:

Clay is the primary material used in the production of traditional bricks. It is abundant in nature and forms the foundation of the brick-making process. Clay consists of fine particles derived from the weathering and erosion of rocks over time. The quality of clay, including its plasticity, moisture content, and mineral composition, significantly affects the properties of the final brick. Different types of clay, such as fire clay or kaolin clay, may be used depending on the specific requirements of the bricks.

Sand:

Sand is a key ingredient in brick-making, acting as a filler and providing desirable properties to the final product. It is typically added to clay in varying proportions to improve the workability, reduce shrinkage, and enhance the structural integrity of the bricks. Sand also helps control the drying and firing characteristics of the bricks during the manufacturing process.

Water:

Water is an essential component in the brick-making process. It is used to facilitate the mixing of clay and sand, forming a plastic clay mixture that can be molded into bricks. Water content affects the workability and plasticity of the clay, allowing it to be shaped and molded into the desired brick form. The right amount of water is crucial for achieving proper compaction and uniformity in brick production.

Additives:

Additives are sometimes incorporated into the brick composition to enhance specific properties or address certain requirements. Some common additives include:

Lime:

Lime is added to clay to improve its plasticity and workability. It helps reduce shrinkage during drying and firing, resulting in more dimensionally stable bricks. Lime can also enhance the durability and resistance of bricks to weathering.

Cement:

Cement is occasionally used as an additive in brick composition to increase their strength and reduce water absorption. The addition of cement helps in the formation of chemical bonds within the brick, enhancing its structural integrity and durability.

Fly Ash:

Fly ash, a byproduct of coal combustion, can be used as a supplementary material in brick manufacturing. It improves the workability and reduces the firing temperature of bricks. Incorporating fly ash in brick composition can enhance their sustainability and reduce environmental impact.

Coloring Agents:

Coloring agents, such as iron oxide pigments, can be added to the brick composition to achieve specific color variations or desired aesthetics.

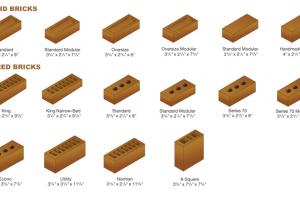

The exact proportions and combinations of these materials vary depending on the specific type of brick being produced and the desired characteristics. Manufacturers carefully control the composition to ensure the resulting bricks meet the required standards and specifications.

Understanding the composition of bricks provides insights into their properties and behavior during construction. It allows builders and construction professionals to select the appropriate type of brick based on the project's requirements, such as load-bearing capacity, thermal insulation, or resistance to moisture. Moreover, advancements in technology and sustainable practices have led to the development of alternative brick compositions, incorporating recycled materials and additives that improve performance and reduce environmental impact.

In conclusion, bricks are a product of careful composition, blending clay, sand, water, and sometimes additives. Each component contributes to the overall properties and behavior of the bricks, determining their strength, durability, and suitability for different construction applications. By understanding the composition of bricks, professionals in the construction industry can make informed decisions and create structures that stand the test of time.