Resource Planning and Cost Management Techniques

Project Control

- Cost control

- Cash Flow Analysis

- Schedule Control

- Material Management

Cost Control

Possible corrective actions could include:

- Adding additional trade workers or crews

- Adding or removing equipment

- Working overtime

- Bringing in additional subcontractors

- Making the job more efficient

- Eliminating factors that cause subcontractors to interfere with each other

Productivity

Let R = Production rate

Where:

T is total time, Q is the total quantity to be installed

The total cost is determined by the equation:

Ct = Ch T

Where

Ct = total cost and Ch = cost per hour, or

Ct = Ch (Q/R)

Cash Flow Analysis

Front Loaded Cost Curve

COST MANAGEMENT

- Includes processes required to ensure that the project is completed within the approved budget.

- Processes involved are:

- Resource Planning

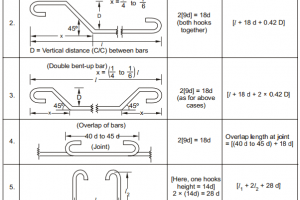

- Cost Estimating (Also See: Bar Bending Schedule)

- Cost Budgeting

- Cost Control

Resource Planning

Involves determining what physical resources (people, equipment, materials etc) and what quantities of each should be used to perform project activities.

Inputs to Resource Planning

-

Work Breakdown Structure:

- A deliverable-oriented grouping of project elements that organizes and defines the total scope of the project. It Identifies the project elements that will need resources.

-

Historical Information

-

Scope Statement:

-

- Contains the project justification and the project objectives.

Resource Pool Description:

-

- Knowledge of what resources are potentially available.

Organizational Policies:

-

- The policies of the performing organization regarding staffing and the rental or purchase of supplies and equipment.

Tools and Techniques to Resource Planning

- Expert Judgment

- Alternative identifications:

- To adopt different approaches for the same problem.

Outputs from Resource Planning

Resource Requirements:

- Description of what types of resources are required and in what quantities for each element of the work break down structure.

Cost Estimating

- Developing an approximation (estimates) of the costs of the resources needed to complete project activities.

- Includes identifying and considering various costing alternatives.

Cost Estimating and Pricing

- Cost Estimating involves developing an assessment of the likely quantitative result-how much will it cost the performing organization to provide the product or service involved.

- Pricing is a business decision-how much will the performing organization charge for the product or service

Inputs to Cost Estimating

- Work Breakdown Structure

- Resource Requirement

- Resource Rates:

- scheduled or non-scheduled

- Activity Duration Estimates

- Historical Information

- Chart of Accounts:

- Describes the coding structure used by the performing organization to report financial information in its general ledger.

Tools and Techniques for Cost Estimating

Analogous Estimating / Top-down Estimating:

- Using the actual cost of a previous, similar project as the basis for estimating the cost of the current project. It is less costly but less accurate. (Rough-cost Estimate)

Parametric Modeling:

- Using project characteristics (parameters) in a mathematical model to predict project costs.

Bottom-up Estimating:

- Estimating the cost of individual work items, then summarizing or rolling up the individual estimates to get a project title. (Detailed Estimate)

Computerized Tools:

- Use of computerized tools such as project management software and spreadsheets to assist with cost estimating.

Outputs from Cost Estimating

- Cost Estimates

- Supporting Details like Scope of work, Calculation sheet, Assumptions made, Possible range of results, etc.

- Cost Management Plan describing how cost variances will be managed.

Cost Budgeting

Allocation of overall cost estimates to individual work items in order to establish a cost baseline for measuring project performances.

Inputs to Cost Budgeting

- Cost Estimates

- Work Breakdown Structure

- Project Schedule

Tools and Techniques for Cost Budgeting

Tools and Techniques for developing project Cost Estimates are used to develop budgets for work items as well

Outputs from Cost Budgeting

Cost Baseline

A time-phased budget that will be used to measure and monitor cost performance on the project. It is developed by summing estimated costs by period and is usually displayed in the form of an S- curve.

Cost Control

Cost Control is concerned with

- Influencing the factors which create changes to the cost baseline to ensure that changes are beneficial.

- Determining that the cost baseline has changed

- Managing the actual changes when and as they occur

Cost Control includes:

- Monitoring cost performances to detect variances from plan.

- Ensuring that all appropriate changes are recorded accurately in the cost baseline

- Preventing incorrect, inappropriate, or unauthorized changes from being included in the cost baseline.

- Informing appropriate stakeholders of authorized changes.

Inputs to Cost Control

- Cost Baseline

- Performance Reports

- Provide information about cost performance such as which budgets have been met and which have not. It also alerts the project team to issues which may cause Problems in the future.

- Change Requests

- These may occur in many forms-oral or written, direct or indirect, externally or internally initiated, and legally mandated or optional. These may require increasing the budget or may allow decreasing it.

Tools and Techniques for Cost Control

Cost Change Control System

- It defines the procedures by which the cost baseline may be changed. It includes the paperwork, tracking systems, and approval levels necessary for authorizing changes.

Performance Measurement

- It helps to assess the magnitude of any variations which do occur.

Additional Planning

Perspective changes may require new or revised cost estimates or analysis of alternate approaches.

Computerized Tools

Outputs from Cost Control

- Revised Cost Estimates

- Budget Updates

- Corrective Action

- Estimate at Completion

- It is a forecast of total project costs based on project performance.

- Lessons Learned

OBJECTS OF COST CONTROL

-

To have a knowledge of the profit and loss of the project throughout the duration of the project.

PROJECT PROFITS

- Client payments.

- Sale of surplus or scrap material and plant

- Payments for plants or labor by others, where, this plant or labor is , from time to time not required for the project.

PROJECT LOSSES

- Labor and site office costs

- Plant costs

- Site overheads i.e. site facilities, access roads and office etc

- Cost of tendering including bonds, insurance, etc.

- Material costs.

- Head office overheads proportioned over all current projects.

To have a comparison between the actual project performance and that conceived in the original project plan.

- Comparison is basically done according to the following bases:

- According to units of production

- According to line items; e.g., labour, material, equipment, overheads, ---