Uses & Design of Flow Equalization Tank

Definition:

Flow equalization is method used to overcome the operational problems and flow rate variations to improve the performance of downstream processes and to reduce the size & cost of downstream treatment facilities. To prevent flow rate, temperature, and contaminant concentrations from varying widely, flow equalization is often used.

Objective

Give a relatively constant flowrate to the downstream operations and processes

Functions of FET

- Dampen the daily variation in flowrate and loadings

- Reduce the required size of the downstream treatment facilities

- Feasible dry weather flows in separate sewer system and sometimes for storm

Effects of flow equalization

- 10-20% of BOD entering is stabilized in the equalization basin

- 23-47% of SS is further removed in the primary clarifier

- reduce shock load on biological process

Why to Use flow Equalization Tanks

Variations occur characteristically in domestic wastewater flow rate and composition as a result of cyclic activities of the human population. Additional variations are commonly imposed by a combination of:

- Random and cyclic activities in the collective industrial-wastewater-generating segment of the community and

- By storm-related effects of infiltration and inflow

- In addition, the average waste water flow rate at typical municipal treatment plants may be expected to increase by 25 to 100 percent or more over the design life of the facilities.

- Operation of waste water treatment plant at uniform conditions is assumed to be advantageous. It results in improved efficiency, reliability, and control of various physical, chemical and biological treatment processes. Costs can also be reduced by elimination of excessive peak treatment capacity and from reduced periods of operation under peaking conditions.

Design of Flow Equalization Tanks

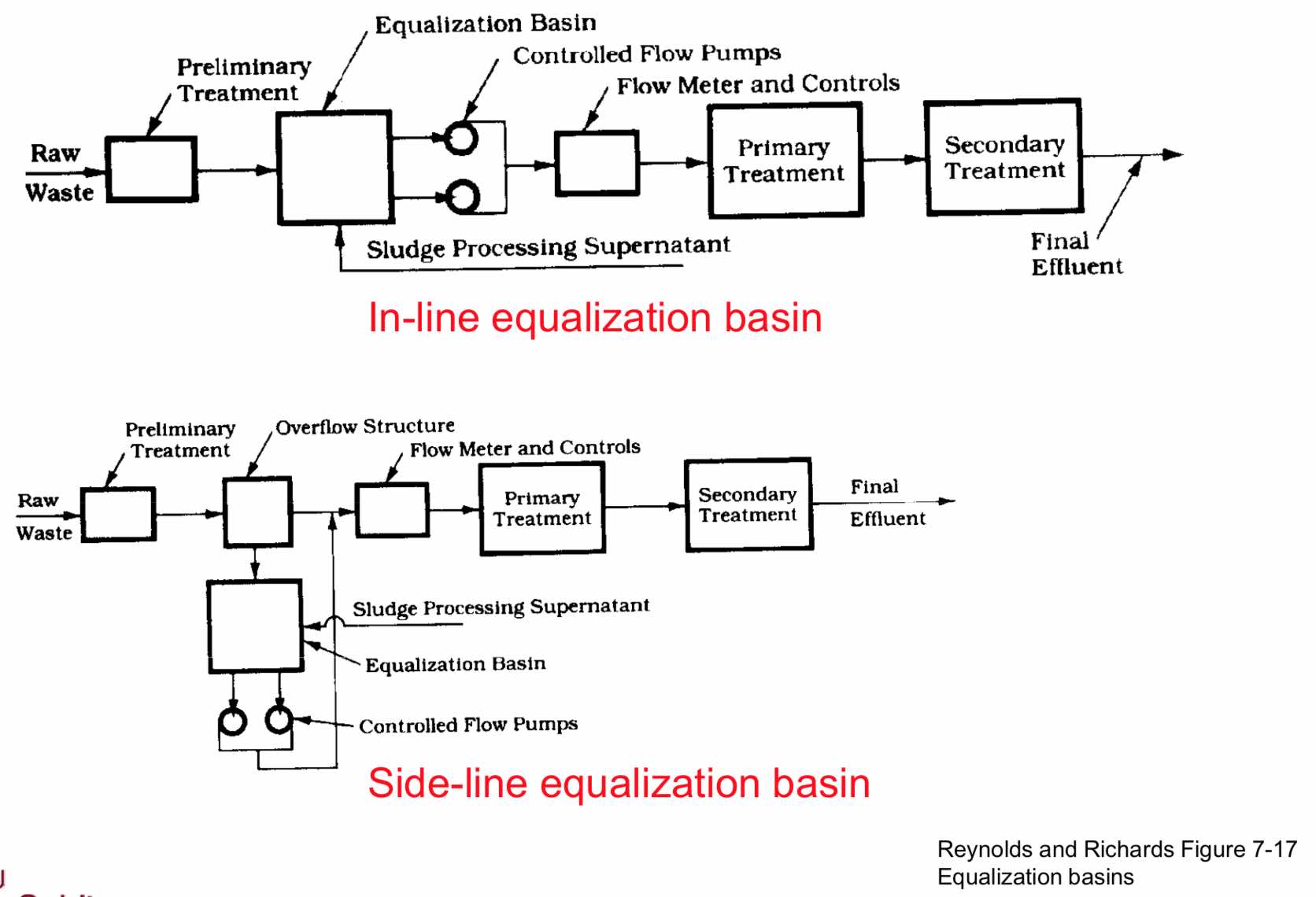

The design of equalization facilities requires evaluation and selection of a number of features:

- Type and magnitude of input variations

- Required volume

- Facility configuration

- Pumping/control mode

- Type of construction

- Appurtenances; aeration, mixing, odor control, cover, flushing

- Cost and benefits

Benefits - Advantages of Flow Equalization Tank

-

Reduction of peaking requirements

-

Reduction of process overloads at existing plants under some conditions

-

Protection against toxic upsets

-

Potential reduction of operational problems

-

Provides increasing benefits with increasing plant complexity

- Placement of equalization following primary treatment minimizes operation and maintenance, and minimizes requirements for solids removal, aeration, and odor control equipment